San Francisco-Oakland Bay Bridge: Permanent Fix for Broken Rods Now in Place

Caltrans has completed the installation of the saddles on the new East Span of the San Francisco-Oakland Bay Bridge, which replaces the seismic safety function of the broken rods and the temporary shims installed prior to the bridge’s Labor Day weekend opening.

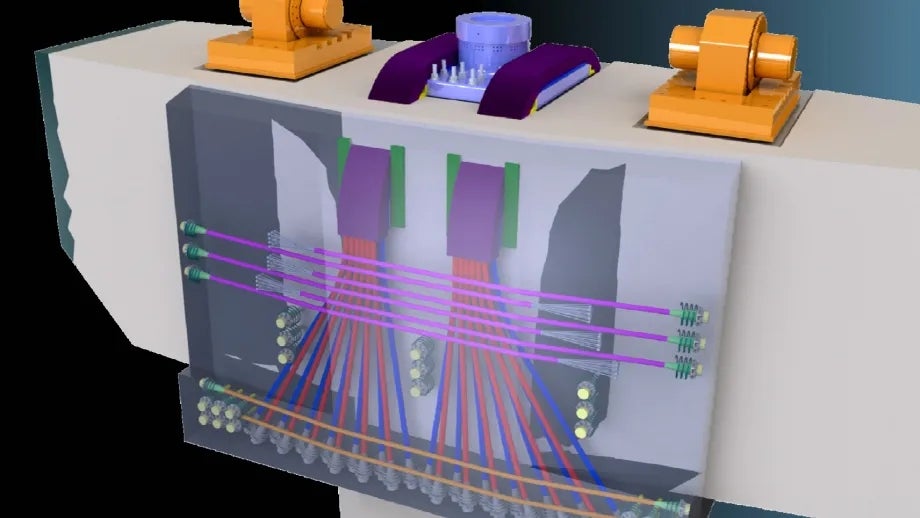

On March 1, 2013, workers began stressing 96 rods to hold down two seismic devices at the eastern pier the bridge’s suspension span; between March 8 and March 15, 32 fractured rods were discovered. The eastern pier contains seismic devices called bearings and shear keys. The bearings allow the road-decks to move slightly during a seismic event, while the shear keys prevent the decks from moving too much. The four bearings (two beneath each deck) and four shear keys (one beneath each deck and two beneath the cross beam connecting the decks) are bolted between the roadways and a concrete cap beam with steel anchor rods. These specific rods are located at the base of the shear keys beneath the road decks.

The rods could not be replaced as they are embedded in concrete and there is not enough clearance to remove them, as they rods range in length from 9 to 17 feet. In May, engineers selected custom-made steel saddles as the fix to exert that same clamping force as the original bolt design to hold down the shear keys.

The saddles sit on top of the base of the shear keys, with steel tendons inside the saddles spreading down either side of the concrete cap beam. The saddles were selected because despite requiring more detailed fabrication, installation will be easier and require less drilling of the concrete cap beam.

While work related to the functionality of the saddles is complete, other work will continue for the next couple of months, including painting the saddles, covering rod heads with caps and removal of the scaffolding beneath the bridge.

The final cost of the saddles, which includes design, fabrication and installation, will be approximately $25 million.

Submit your comment

In order to receive a reply to your comment, please provide an email address.