A machinist mills a piece of the Bay Bridge's steel saddle.

Not labeled for reuse. All rights reserved.

A worker checks specifications on a piece of the Bay Bridge's steel saddle.

Not labeled for reuse. All rights reserved.

A worker mills a piece of the Bay Bridge's steel saddle.

Not labeled for reuse. All rights reserved.

Workers walks through XKT Engineering's Mare Island facility.

Not labeled for reuse. All rights reserved.

A portion of the Bay Bridge's steel saddle

Not labeled for reuse. All rights reserved.

Shavings cover a table as a machine cuts a portion of the Bay Bridge's saddle, top right.

Not labeled for reuse. All rights reserved.

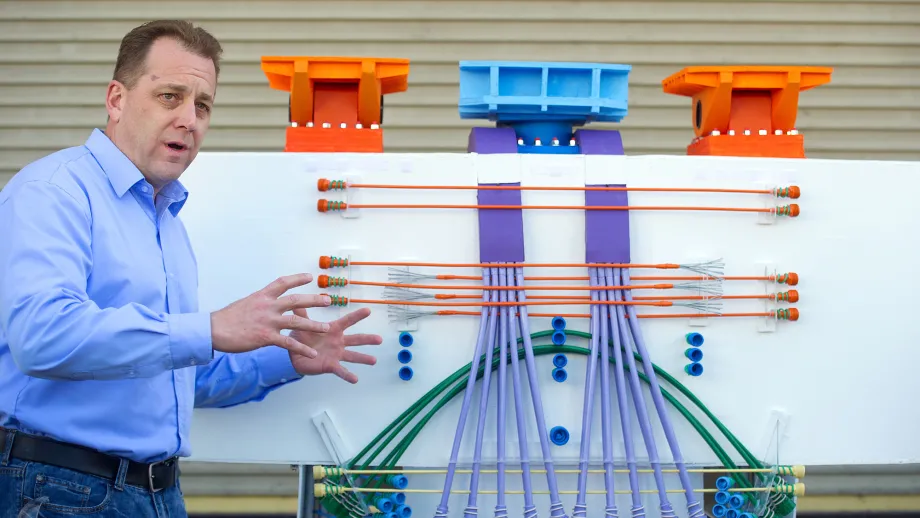

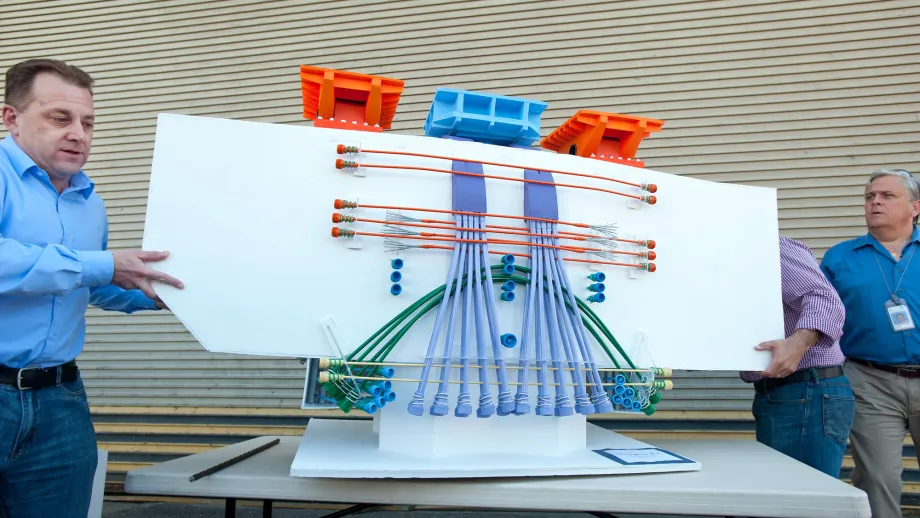

Bill Casey, resident engineer for the Bay Bridge's SAS project, uses a model to explain how post-tensioned tendons will reinforce the East Span.

Not labeled for reuse. All rights reserved.

Bill Casey demonstrates a model of post-tensioned tendons that will reinforce the East Span.

Not labeled for reuse. All rights reserved.

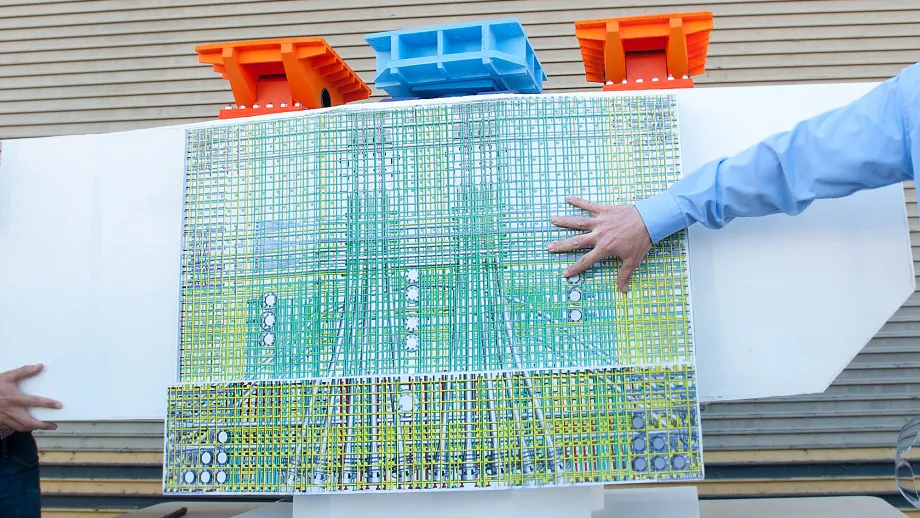

A diagram of rebar that will be used in constructing the East Span's saddle

Not labeled for reuse. All rights reserved.

Not labeled for reuse. All rights reserved.

Journalists tour XKT Engineering's Vallejo, Calif., facility where pieces of the Bay Bridge's saddle, seen at bottom, are being fabricated.

Not labeled for reuse. All rights reserved.

A pedestrian passes a vista of Mare Island on Wednesday, Aug. 31, 2013, in Vallejo, Calif. XKT Engineering, located at the former naval shipyard, is fabricating a steel saddle that will reinforce the Bay Bridge's new East Span.

Not labeled for reuse. All rights reserved.

Members of the media were invited yesterday to tour the steel plant in Vallejo that is fabricating key parts of the saddle system that will help secure seismic gear on the new East Span of the San Francisco-Oakland Bay Bridge. The saddle system will replace the clamping force of bolts that broke in March 2013.